Carbon Alternatives can help in the design, commissioning and operation of district heating systems. Our experience is that many UK M+E designers are unaware of the design subtleties required for DH to deliver lowest lifecycle costs. Drawing from experience of operating schemes we have good knowledge of what works and what doesn’t. A common finding when reviewing the design of a proposed DH scheme is that both capital costs and operating costs can be reduced. Put simply many schemes are over complicated and over sized. An additional problem is that often Energy Strategies are written to to get planning permission, and don’t consider the economics of the heat network operation, and the M+E designer needs to deliver the plant as per the Energy Strategy.

A weakness of procuring a DH design from a typical M+E consultant is that most consultants never get the opportunity to be involved in the operation of schemes beyond initial commissioning. During commissioning it’s common that any issues arising are put down to the there being no heat load. It’s only through operating and monitoring live schemes that good design and what isn’t good design is categorically demonstrated.

The earlier in the design process that we can get involved the greater the potential benefits are, but we find scope for low cost / zero cost improvements even on operating schemes. As mentioned above getting the energy strategy correct is key and a small input at this stage can save much cost later.

Typical design recommendations:

- The sizing of the low carbon / renewable heat source and thermal store show be done on an econimic basis. Occasionally the plant sizing may be undertaken to maximse the carbon savings, but in operation most systems are set up to achive the lowest operating cost and not lowest carbon emissions.

- Challenge oversized plant, boilers pumps etc

- Question the use of heat exchangers

- Commonly the hydraulic connection of the boiler / CHP / thermal store prevents system operating effectively

- Question use of bypasses

- Question pump sizing

- Check efficiency of system operation at low heat loads, as low loads are the most common operating condition.

- Does the design allow the use of a economically optimised CHP or heat pump operation strategy

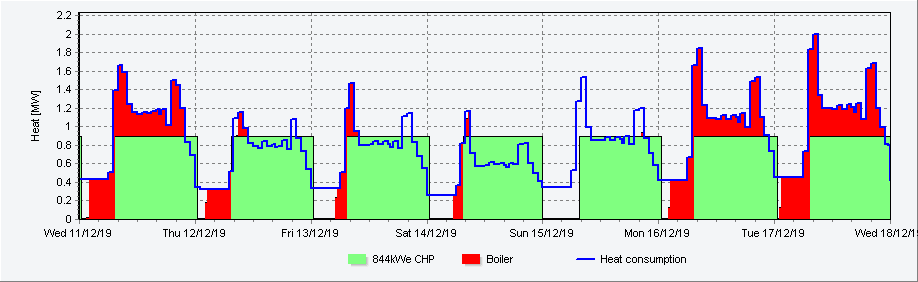

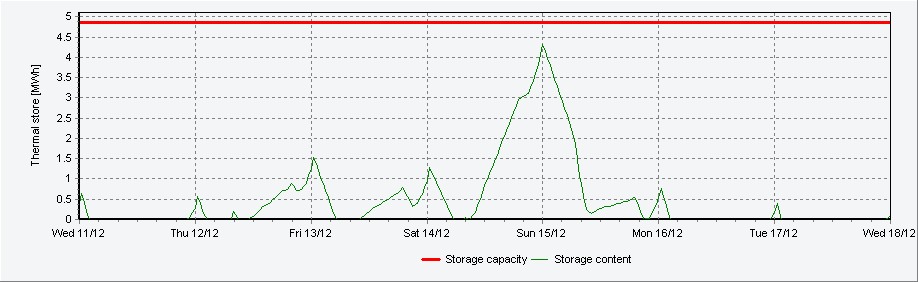

Using energyPRO we can model the operation of heat and cooling networks, with a range of heat sources, CHP to solar thermal with thermal storage. From the modelling we optimise plant sizing and assess the economics (capital and operating costs) of the range of technical solutions to achive lowest lifecyle cost. Example of energyPRO below:

There is more information on eneryPRO and other tools on the modelling tools at heat network modelling tools